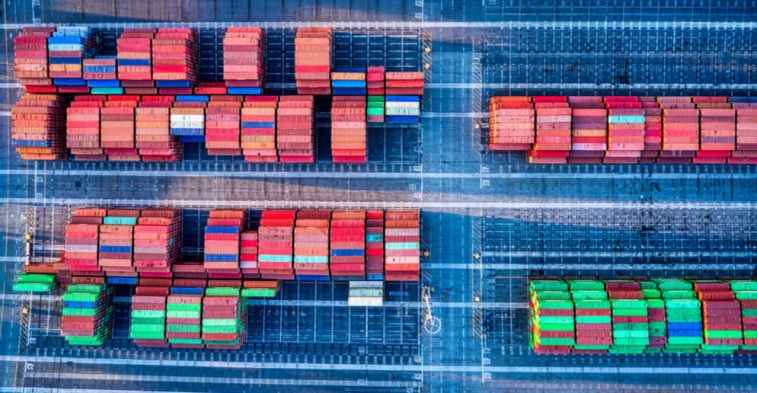

The True Issues Facing Shippers and Importers in this Supply Chain Nightmare – and How We Face Them with Resilience

It shouldn’t come as a surprise to anyone in the industry that trade will remain incredibly tight for the remainder of 2021 and through 2022, with constraints resulting mainly from port infrastructure challenges, demand variability, COVID-19 resurgences, and carrier capacity.

“Global supply chain bottlenecks are feeding on one another, with shortages of components and surging prices of critical raw materials squeezing manufacturers around the world,” wrote reporters for the Wall Street Journal in an Oct. 8 story.

I recommend to any executive seeking guidance that all aspects of their business ought to focus now on resilience. Engage your partners and stakeholders with transparency about the challenges; don’t try to shield them from reality. Leaders need to concentrate on business continuity and supply chain agility, whilst scenario planning throughout the value chain of inputs and flows.

Even when it looks like conditions are approaching catastrophe, there is always something an organization can do. After the 2014 flooding in Somerset, Prince Charles visited the area to learn about relief efforts and remarked, “There’s nothing like a jolly good disaster to get people to start doing something.”

Now is a good time to remind managers that they need not wait for a jolly good disaster to create a plan of action. Rather, multiple “scenario plans” are crucial to providing guidance in the case of any disruption one can think of — and they must include mechanisms for coordinated communication and implementation across the value chain. Making sure these scenario plans result in opportunities for reserving capacity within manufacturing and transport divisions will allow your company to switch gears when needed.

Any company that relies on a global supply chain is suffering to a degree right now. Obstacles have descended like a game of whack-a-mole; if capacity is secured, an issue like port congestion is ready to pop up and take its place as the bottleneck. That’s why I’ve been reminding my teams and customers that rather than keep strict, minute-by-minute tabs on external conditions, our time is better spent referring to (or developing, if none are found to be applicable) our scenario plans to discern what levers to pull, as well as the potential customer impacts.

The best path toward actually implementing these chosen plans of action is consistent collaboration, transparency of information, and gaming with peer options/scenarios. It is also worthwhile considering that options are changing rapidly as providers, countries and infrastructures adapt — e.g. options you thought open today, may not exist tomorrow — so being present (understanding the landscape) is as important as planning scenarios in advance.

The fundamental concept of trade, as outlined by Adam Smith in The Wealth of Nations (1776) is based on the concept of comparative advantages and division of labor offset against the cost of home manufacture and transport. If you ask modern-day economists, global trade conditions are a direct consequence; they echo the very same sentiments as Smith expressed in 1776. They produce daily figures such as PMI, GDP growth, wage inflation, etc., which do provide insight into trends that will directly impact the demand for global trade — outside of trade disputes, pandemics and government interventions, that is!

For more informed predictions, however, one must pair economists’ numbers with trade capacity data. We are trying to return to a normal state of demand and supply right now — with one challenge being that speed of recovery and capacity constraints are creating the real impacts, and this is only solved by normalization of demand, which is impacted by both inflation and opening of service sectors (or fundamental societal changes — don’t underestimate the potential for change from COP26); and/or increased capacity to service demand, which would require new vessels and terminal infrastructure that would be several years out from use.

The last two years have highlighted the fragility of global supply chains, as well as the interconnectedness of our world in general. We’re still feeling the effects of the initial COVID-related factory shutdowns in Wuhan, which immediately generated a global impact on supply chains. COVID has shown how shocks in long global supply chains can become impossible to repair, destroying businesses and wiping out hard-fought GDP growth.

Among the most likely outcomes: companies will re-evaluate risk in sourcing internationally, consider more diverse sourcing strategies, and build segmented supply chains to manage risk.

We must be mindful, however, that while the majority of the news over the last two years has been about COVID, major geopolitical changes have also been playing out: heightened tensions between the US and China, increased risk of conflict in the Asia Pacific region, and trade tensions between the UK / EU through Brexit. So when companies look at long-term strategy, these influences on trade policy may force more questions over resiliency, risk management, and diversity than the pandemic’s impact.

Also among the headlines is ongoing discourse about the US’s over-dependence on foreign supply, both in terms of resilience and sustainability agendas.

In the short run, keep in mind that big problems very often don’t have simple solutions. We can manage the diversity of sourcing both nationally and internationally, remembering that even domestic supply chains are not 100% safe from natural disasters and environmental impacts. We can segment our supply, understand the sourcing of inbound products, and take steps to secure strategic inputs that the company depends on — all while utilizing a diversity strategy that blends domestic, near-sourced, and internationally sourced inputs from diverse supplier bases.

Apart from the above actions, it’s good old effective planning, careful inventory adjustments, and sales management that remain the keys to supply chain resiliency, whether near- or far-sourced.

_______________________________________________________________________

Neil Wheeldon is Chief Strategy & Innovation Officer, BDP International. He is an experienced supply chain management practitioner having worked across numerous industries supporting customers in supply chain and digital transformation initiatives to drive growth. He can be reached at neil.wheeldon@bdpint.com.

Leave a Reply