Innovating Warehouse Efficiency: Gather AI Introduces Drone-Powered Inventory Solutions

Gather AI, renowned for its computer vision-based AI solutions for warehouse inventory monitoring, unveils two groundbreaking capabilities: inferred case counting and location occupancy. These pioneering features empower warehouses with automated, digitized inventory counts and precise space utilization insights, promising improved shipment efficiency and reduced labor costs associated with manual counting.

Ensuring accurate inventory levels is paramount for warehouse operators to meet shipping deadlines and optimize storage space. However, manual counting methods are not only labor-intensive but also prone to inaccuracies, exacerbating logistical challenges. According to the Warehousing Education & Research Council (WERC) 2023 DC Measures Annual Survey & Report, the average warehouse achieves shipping deadlines only 96% of the time, with a cube utilization of 81%.

Gather AI’s solution revolutionizes this process, enabling warehouses to scan up to 900 pallets per hour using drones equipped with advanced computer vision technology. By capturing images of each location, the AI swiftly analyzes multiple barcodes and text, identifying empty spaces and providing inferred case counts for both full and partial pallets. This real-time data, accessible through the customer web dashboard, streamlines inventory management and facilitates space optimization, mitigating the need for manual cycle counting and minimizing the risk of missed shipments.

AJ Raaker, Director Of Warehouse Development at Taylor Logistics Inc., attests to the efficiency gains achieved with Gather AI’s solution, stating that inferred case counting is 87% more efficient than traditional physical cycle counting methods. This efficiency boost enables teams to focus on revenue-generating activities while ensuring inventory accuracy.

The newly introduced capabilities further enhance operational efficiency:

– Inferred Case Count: Warehouse operators can reduce manual counting time by 90% by leveraging computer vision and AI to estimate case counts on pallets. Pallets with low case counts are flagged for replenishment, preventing stockouts and missed shipments. Labor can be prioritized by focusing on pallets deviating from the WMS expectations.

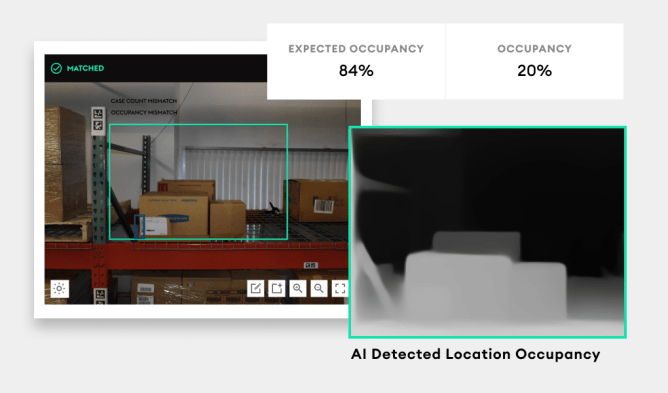

– Location Occupancy: Warehouse operators gain insights into space utilization, identifying opportunities for pallet consolidation and maximizing fixed expense efficiency. Computer vision technology measures available space on pallets, pinpointing consolidation opportunities to optimize storage.

Sankalp Arora, Ph.D., CEO, and Co-Founder of Gather AI, underscores the company’s commitment to delivering real-time inventory insights to warehouse operators. By harnessing computer vision and AI capabilities, Gather AI aims to alleviate labor-intensive tasks and provide unparalleled inventory visibility, empowering warehouses to operate more efficiently and effectively.

Leave a Reply